Why Circularity Requires Engineering

Circularity in textiles is often discussed as a sustainability goal—but in practice, it is a material-engineering challenge, not a marketing initiative.

Recycled materials only work at industrial scale when the inputs, processes, and outputs behave predictably.

The Real Challenge

Most recycling systems fail because of three technical gaps:

Unstable waste streams with varying colors, fiber lengths, and contamination

Inconsistent material behavior that limits use in high-performance applications

Lack of reliable data and traceability, making audit compliance difficult for brands

What Global Brands Need

To integrate circular materials into long-term programs, brands require:

How We Can Solve This

We address these requirements through a structured materials-engineering approach:

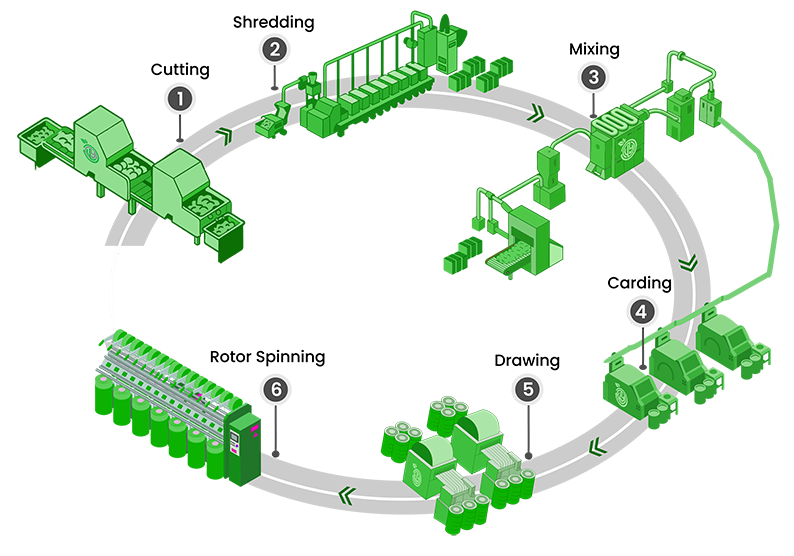

Our Mechanical

Recycled Cotton Spinning Process

At Usha Yarns, we only use the best textile fiber recycling and spinning technologies available to spun our yarns. Our quality and research team work continually to improve each detail of our manufacturing processes to ensure you to get the best quality yarns which surpass the highest standards of any recycled yarn textile manufacturing company.

Thanks to our hardworking team, we have successfully implemented a spinning recycling process using optimized operational methods to efficiently transforms garment cutting fabric waste into flawless recycled yarns suitable to meet your woven and knitted fabrics needs.